NAXOS-DISKUS Schleifmittelwerke GmbH

NAXOS-DISKUS, with a legacy of over 150 years of experience in grinding and abrasive technologies. We deliver high-quality OD and ID grinding solutions that are engineered to meet exact process requirements. Our products are developed at the cutting edge of technology, ensuring reliability, consistency, and performance. Customer focus is at the core of everything we do, shaping solutions tailored to real production challenges. State-of-the-art manufacturing facilities ensure the highest standards of quality and precision. Through knowledge and technology transfer within the DVS TECHNOLOGY GROUP, we provide integrated and future-ready solutions.

Internal and External cylindrical grinding wheel

External cylindrical grinding is one of the most common methods used for the grinding of camshafts and crankshafts. Our solutions are best suited for the materials most commonly machined in rough grinding, finishing and angled plunge-cut grinding.

We enable the highest precision for every field of application by individually selecting the structure of each grinding wheel according to the individual specific application of our customers.

External Cylindrical Grinding

It is one of the most common methods used for the grinding of camshafts and crankshafts. Our solutions are best suited for the materials most commonly machined in rough grinding, finishing and angled plunge-cut grinding.

We enable the highest precision for every field of application by individually selecting the structure of each grinding wheel according to the individual specific application of our customers. The manufacture of grinding wheels with a diameter of up to 1,600mm is one of our many specialities. With our XXL external cylindrical grinding wheels and experience of over 150 years of production of abrasives, we can offer solution for just about any processing size.

Centerless Grinding Wheels

For this particular application, a distinction is made between feed-through grinding and plunge grinding. Depending on the situation, you can choose between a single-piece and a multi-piece variant. This may improve the handling when changing grinding wheels, depending on the circumstances. Maximum accuracy and precision in the design and manufacture of the transitions of multi-part wheels is particularly important to avoid impressions of the latter on the grinding pattern. We manufacture these areas with different grain sizes and hardnesses in order to ensure a high cutting rate on the infeed side, especially during through-feed grinding, and a good surface quality on the run-out side.

Crankshaft Grinding Wheels

This unique type of grinding wheel generally uses ceramic bonds. Depending on the type of grinding task, the grinding wheel for bearing seats can be built up in one layer or, if the shoulders and the bearing seat are to be ground in a single pass, also in three layers. We can manufacture these wheels very precisely in multiple layers. The three-layer design also increases the durability of the crankshaft grinding wheels due to higher stability. The fact that our grinding wheels meet the stringent production tolerances of engine manufacturers, among others, is indicative of their uniqueness and a testament to our proven know-how

Mounted Point – Internal Grinding Wheels

Our mounted points are used for internal cylindrical grinding. These can be made from conventional abrasives as well as CBN mounted points. CBN mounted points yield a longer service life of the grinding tool. The mounted points from NAXOS-DISKUS are extremely reliable under difficult conditions and at high speeds. They are especially useful for use in hard to reach places.

In future, mounted points will be used for time-saving simultaneous grinding in many cases. Once again, you can rely on NAXOS-DISKUS as the manufacturer of every conceivable type of abrasive.

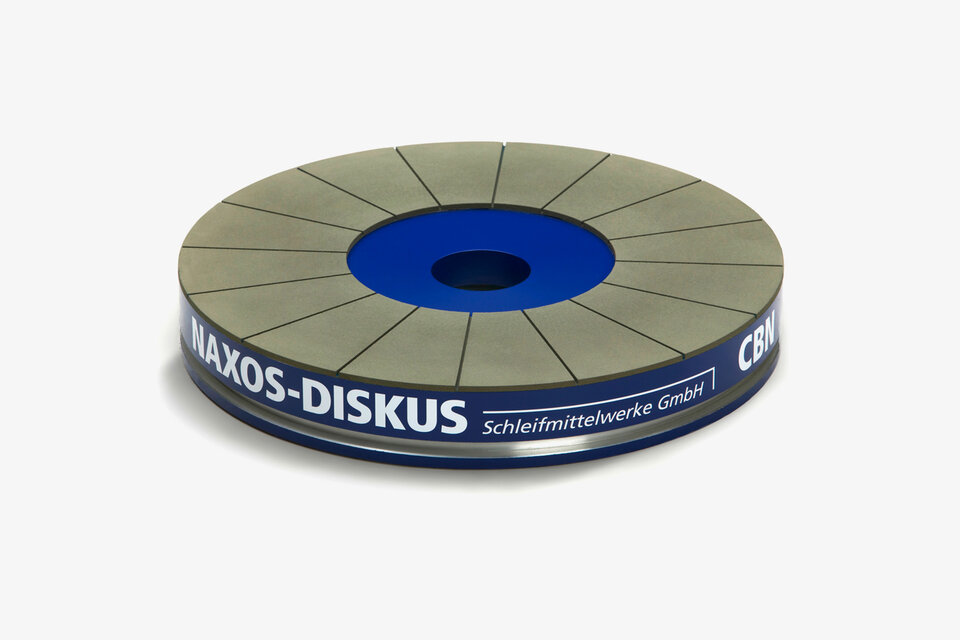

Disc Type Grinding Wheel

In industrial use, surface grinding of workpieces is often a basic requirement, such as for cylinder heads where absolute evenness is critical. This process entails a wide range of variations and possible uses – it is used in the tooling, ceramics, and automotive industries, among others, where cylinder barrels, housings, covers, or cylinder heads are processed to render the sealing surfaces completely flat.

Conventional Disc Grinding Wheels

For conventional disc grinding, we are the original equipment manufacturer for the famous double-disc grinding machines from DISKUS WERKE. Our many years of working with our partner has enabled us to manufacture grinding wheels for every suitable application case. Some of the areas of application for conventional grinding wheels are the automotive industry (from engine blocks to conrods), punching, or grinding skies! What makes our grinding wheels unique is the high and consistent quality and dimensional accuracy with an unbeatable price-performance ratio.

NAXOS-DISKUS can look back on many years of experience in the manufacture of CBN and diamond disc grinding wheels. Our discs are used for many different types of metal and ceramic machining, such as for the grinding of piston rings. These grinding wheels offer a long service life and high dimensional accuracy of the ground workpieces. Our grinding wheels can optionally be covered with a base body made of steel or aluminum. Our ceramic and synthetic resin bonded CBN and diamond disc grinding tools offer complete peace of mind for the future.

CoolEdge GrindPro is the latest innovation in a grinding wheel designed to revolutionise double face grinding. Heat-sensitive workpieces such as ceramic components are workpieces for which CoolEdge GrindPro is particularly suitable. The challenge of double face grinding is that the workpiece must be ground flat to the µ with a high stock removal of up to 1.6 mm. A newly developed, innovative resin ensures a low, adjustable bond quantity. This makes the grinding wheel grain-rich, soft-grinding and excellently dressable. Another plus is the improved wet grinding resistance, which is also due to the newly developed resin. CoodEdge GrindPro stands for “high stability”, “cool grinding” and “lower machine load”, aspects that relate to the machining of materials, especially in the industrial sector.

NAXOS-DISKUS produces grinding segments for a wide range of applications.

The advantage of grinding segments is their ease of installation in the grinding machine. They are also perfect for rough machining to maximize the dimensional and surface properties. One of the possible uses is the grinding of engine blocks. Another example are ball cages that are ground on one side.

CBN and DIA Grinding Tools

In the machining of extremely wear- and abrasion-resistant materials, maximum processing speed and precision are required nowadays. NAXOS-DISKUS has a wide range of tools with diamonds and CBN for the efficient machining of amorphous materials or carbide-containing alloys.

External cylindrical grinding

Our CBN and diamond grinding wheels enable extremely accurate grinding performance with excellent repeatability. Specially coated CBN grit and newly developed ceramic and synthetic resin bonds form the basis for your CBN and diamond grinding wheels from NAXOS-DISKUS. These special CBN grinding products are used for the machining of very hard and carbide-containing alloys. They can also be used for excellent grinding results with materials such as tool steels, specialty steels, and much more. Our diamond grinding wheels feature maximum hardness, which is why they are also suitable for the machining of amorphous and extremely hard materials.

Made for professionals by professionals!

Dressing Tools

Since the introduction of CNC-controlled dressing processes, the number of CBN and diamond form dressing rolls on the market has increased significantly. In working closely with DVS Tooling GmbH and BUDERUS Schleiftechnik GmbH, our goal is to reduce the type diversity in order to achieve more streamlined warehousing and more cost-effective tool production. DVS TECHNOLOGY GROUP thus enables users to make their grinding processes more economical.

Dressing of the grinding wheel enables precise concentricity and a correct geometric shape on the grinding wheel. In addition, dressing is used to profile or calibrate grinding wheels. Dressing also removes impurities from the grinding wheels caused by material abrasion and the blunted abrasive grits, and it lays bare the sharp abrasive grits. This reduces heat generated during the grinding process and keeps the required removal rate constant.

Diamond dressing rollers are available in different designs. While natural diamonds are the norm, industrial diamonds are also used more and more frequently. The materials used are MKD, CVD and PCD. Due to their defined shape, they guarantee constant and reproducible quality over their entire service life. Since the introduction of CNC-controlled dressing processes, there are many CBN and diamond form dressing rolls on the market. In working closely with DVS Tooling GmbH and BUDERUS Schleiftechnik GmbH, NAXOS-DISKUS Schleifmittelwerke GmbH want to reduce the types diversity to a normal level in order to achieve more streamlined warehousing and more cost-effective tool production. DVS TECHNOLOGY GROUP thus enables users to make their grinding processes more economical.

Special Products

Each tool has very unique requirements. The more we know about your application, the easier it is for us to offer you the best possible specification – for us, every good solution starts with listening closely.

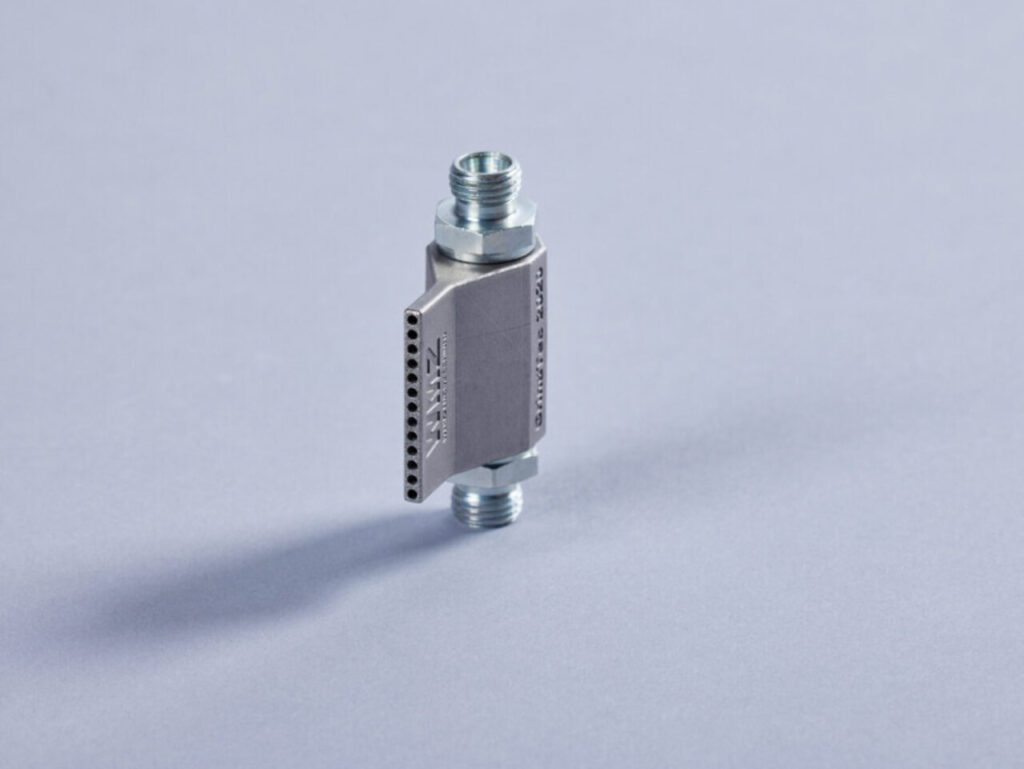

Cooling nozzles

Efficient cooling nozzles keep temperatures constant and prevent burn marks in the grinding process. Precise cooling minimises wear, which extends the life of your tools. Fewer tool changes mean more efficiency and lower expenses. In addition, cooling nozzles result in lower coolant requirements and maximise the cooling effect with minimal amount of coolant. This not only saves costs, but also protects the environment. Longer tool life is the result of optimal cooling. The combination of precise cooling and minimal downtime leads to an impressive increase in your productivity.

Our cooling nozzles offer the ideal solution for optimum process cooling in grinding technology. Rely on quality, efficiency and reliability to achieve the best results.

Grinding discs

As the OEM for grinding mill manufacturers, we can offer extensive experience. And we can guarantee a level of quality that has been constant for decades. The food sector also uses our products. The long shelf life and optimal dimensions of our precisely manufactured grinding discs are a win-win for our customers – which is why a wide variety of users appreciate them. Of course, we will tailor the product precisely to your requirements. This includes grinding discs of any shape and size and for a wide variety of products, such as mustard, cacao, or coffee.

Nurit rollers

Nurit rollers or also yarn guide pulleys are an indispensable aid for the textile industry. The thread which is partially immersed into coolant is optimally moistened and guided, even at high peripheral speeds. Excellent, heat-absorbing properties and extremely precise workmanship support the faultless manufacture and processing of textile threads. Due to the excellent capacity to absorb coolants, you no longer need to worry about faults or downtime in the manufacturing process. Moreover, we would be pleased to configure specific Nurit rollers according to your individual requirements.

Loose abrasives

Our regular and special fused aluminum oxides, which are especially designed for surface treatment, are suitable for use in bonded abrasive bodies as well as for the abrasive blasting of workpieces. Due to their high purity and abrasion resistance, excellent surfaces are obtained by the abrasive blasting process. If desired, we can also supply you with very homogeneous mixed corundum, which is prepared in our mixing units. Extensive storage capacity ensures prompt delivery of individual quantities.

The chemically neutral blasting abrasives made by NAXOS-DISKUS are characterized by high purity and can be processed without any health risk. They are perfectly suitable for matting, deburring, blast cleaning, and shot peening.