Indusa GmbH are an innovative, family-run company based in Neu-Anspach -Germany. With expert advice and customized air-filter construction, we will find the right solution for you. Our strengths include first-class advice, personal support, quick and individual problem-solving, as well as customer proximity. It is important to us that you fully enjoy the benefits of our air filters. For more than 40 years Indusa have provided customised solutions for your air problems.

Indusa Products

We are happy to share our many years of experience in the field of filtration and air pollution control with our customers. This is reflected in the constant improvements of our products. With our wide range of flexible product range, we can offer you a solution ideally suited to your needs.

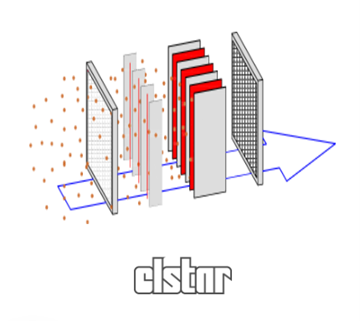

Electrostatic air filter – elstar

Electrostatic oil and emulsion mist separator/Electrostatic exhaust system

Vertical air filtration systems

Vertical air filters, whether mechanical or electrostatic, extract the polluted process air at the bottom of the housing. The polluted air then passes through the filter unit in the filter and is blown out at the top of the housing. The air to be cleaned flows vertically through the filtration system.

Horizontal air filtration systems

Horizontal air filters, whether mechanical or electrostatic, extract the polluted process air at the left or right of the housing. The polluted air then passes through the filter unit in the filter and is cleaned and blown out on the other side of the housing, usually upward. The air to be cleaned flows horizontally through the filtration system.

Duct separators

Duct separators are electrostatic filter systems without their own fan. The system is integrated into a central ventilation system with ventilation.

Equipment

We stock a wide range of accessories for our elstar products.

Amongst other things:

• Drip frames

• Chassis

• Drip tray

• Wall mount

• 4-foot stand

• One-column stand

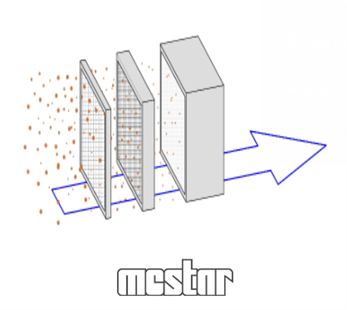

Mechanical air filter – mestar

As one of the few devices on the market, the mestar air filter can freely control its suction volume. Thus, the suction power can be kept constant at the set value for as long as possible. Thanks to the changing of operating point, the filter is the ideal companion for machine tools of all kinds.

The mechanical air filter is used for the separation of oil mist, emulsion mist, oil smoke, haze, suspended particles, oxide-containing smoke, aerosols, etc. – making it suitable for almost any industrial application.

Depending on the application, the devices can be equipped with a variety of filter levels. An extension or optimization can also be done

Vertical air filtration systems

ML 800 to ML 1500

Mechanical air filter with a suction capacity of up to 1,700 m³/h.

flows vertically through the filtration system.

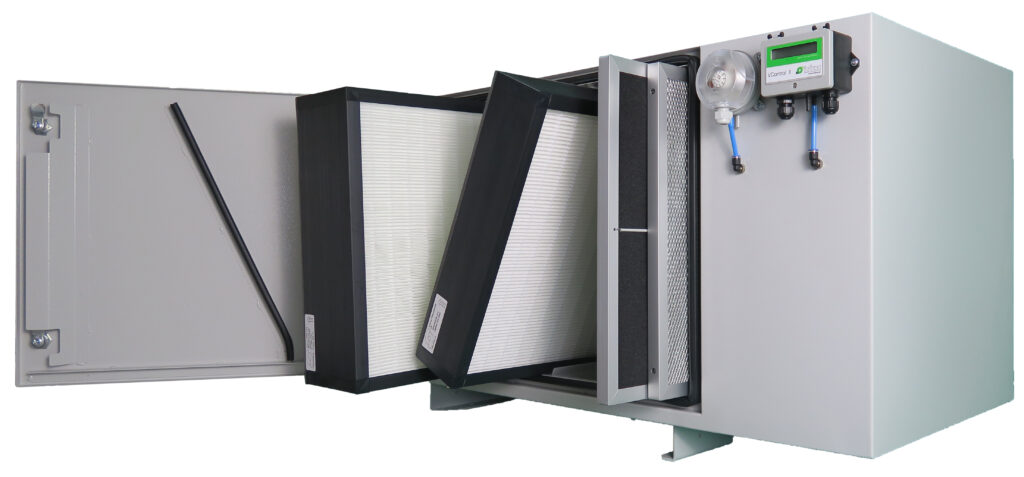

Horizontal air filtration systems

ML 802 to ML 1502

Mechanical air filter with a

suction capacity of up to 1,700 m³/h.

ML 3002 to ML 9002

Mechanical air filter with an

extraction capacity of up to 10,200 m³/h.

Consumable

- Pre / after filter G2

- Prefilter complete G4

- Pre-filter replacement fleece G4

- Filter panels F9

- Post-filter HEPA H13

- Post-filter activated carbon

Equipment

Indusa stock a wide range of accessories for our mestar products.

Amongst other things:

- Drip frames

- Chassis

- Drip tray

- Wall mount

- 4-foot stand

- single-column stand

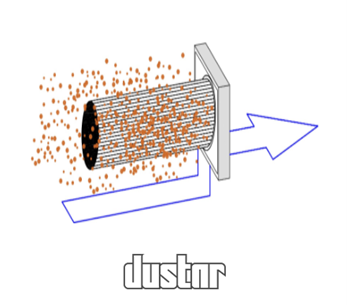

Dust filter – dustar

The range of dustar dust filters ranges from simple vibrating bag filters to large cartridge filters.

Its field of application covers almost all dust applications, such as:

- Welding fumes

- Metal dust

- Glass dust

- Ceramic dust

- and much more.

All dustar filters have been carefully designed to generate the lowest possible loss in pressure, with the highest possible degree of separation.

This gives you the benefit of saving energy costs permanently! From conventional IE2 motors to modern IE4 motors, which exceed all energy-saving requirements. A comprehensive range of accessories is available for all indusa dust filters, to perfectly match the devices to your application!

Vibrating bag filter system

Vibrating bag filter system with a suction capacity of up to 2,000 m³/h.

• DL 900

• DL 200

Cartridge filter

Dust filter system with an extraction capacity of up to 5,000 m³/h.

• DL 1100

• DL 2000 till 5000

Wet separators – nastar

Wet separators based on the vortex washer principle for separating harmful dusts

The wet separators in the nastar series are the right solution for problematic dusts, whether they are sticky, moist, flammable or explosive. Almost all dusts that cannot be separated using our dust filters in the dustar series are optimally captured using the wet scrubbers in the nastar series.

The main reasons for using the nastar wet scrubbers are:

- No risk of fire or explosion.

- No clogging or sticking of filter media.

- Long filter service life. Can be extended again in conjunction with the optionally available sludge dredger.

No regeneration phases (e.g. by cleaning). This makes the nastar system very suitable for 24/7 use.

Vortex Washer

The vortex washer principle ensures that the dust particles are wetted with water and sink directly into the water basin. This prevents a flammable or explosive atmosphere. The vortex chamber wets finer dust particles with water so that they can also sink into the water basin. Particles with a size of up to 0.5 µm are separated by 99%. In a drip zone, swirled water droplets can settle and run off into the water basin. The water level in the filter system is constantly monitored and continuously supplied with water via a permanently installed water connection. The dosing device enables the addition of liquid additives. These additives reduce the surface tension of the water and improve the sinking behavior of the dust particles; corrosion protection can also be added. A siphon enables floating particles to be removed. The optionally available sludge dredger extends the service life of the filter system. A silencer on the air outlet side reduces the sound level and noise emissions and contributes to noise protection..

Central systems

A central system allows the optional usage of recirculation or exhaust air operation. This helps save energy in winter.

There is also a simple structure of different exhaust air and filter concepts. The central location also means there is only one central maintenance point. By choosing the individual ventilation units wisely, maintenance can be done without having to shut down the filter system.

This means that filter operation continues during maintenance.

In particular, it is easy to install heat-recovery components in the central system to save on further energy costs.

Further benefits of central systems:

- Air volume: Up to 30,000 m³/h per device.

- Upstream/downstream connection of different filter types and stages, e.g. cyclone separator, activated carbon, HEPA filter

- Vertical and horizontal designs

- Customized ventilation systems

- Central control/special control (SPS)

- Customized designs

- Individual solution concepts